[ad_1]

[ad_1]

This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.

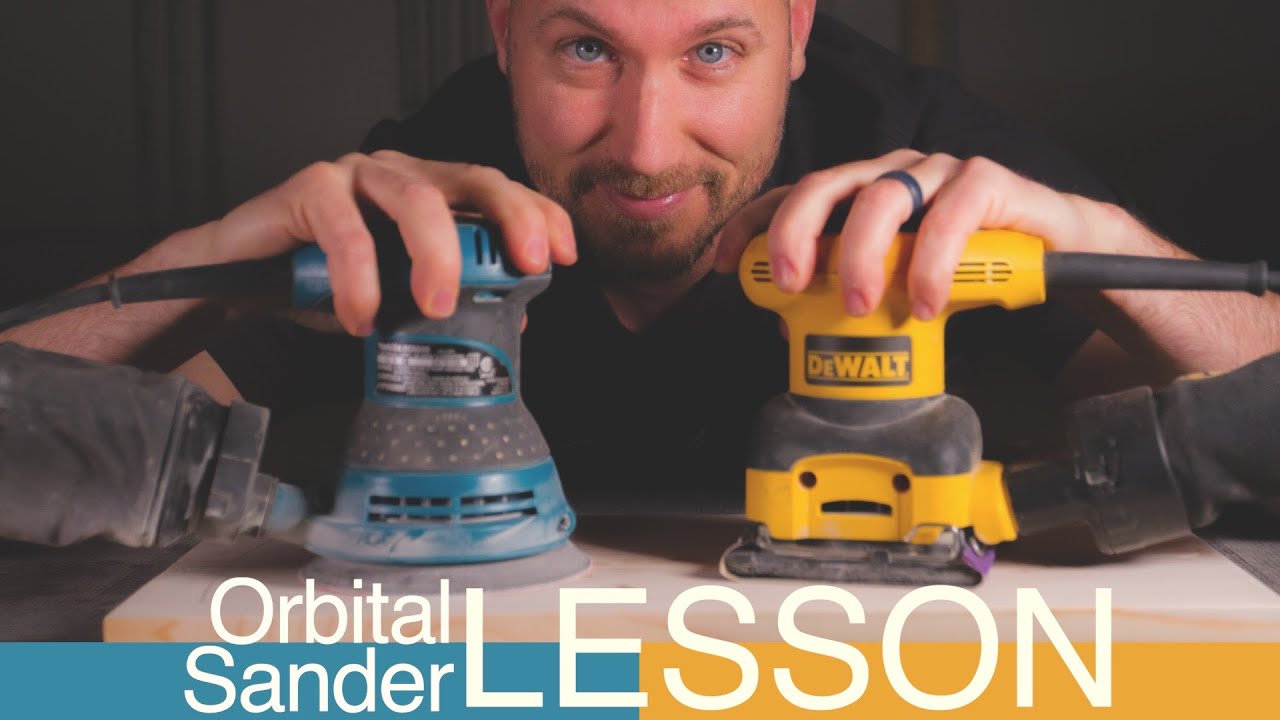

An Introduction to Orbital Sanders and Basic Sanding Techniques

When it comes to achieving a smooth and even finish on woodworking projects, proper sanding techniques are a must. Sanding is an essential step in preparing the surface of the wood before applying a finish. However, many people overlook the importance of using the right tool for the job, leading to frustration and unsatisfactory results. In today’s video, we will be focusing on orbital sanders, covering basic sanding techniques, the different types of orbital sanders on the market, sanding progression, and dust collection.

Types of Orbital Sanders

Orbital sanders are categorized based on the size of the sanding pad and shape of the sanding pad. The two main types of orbital sanders are the standard orbital sander and the random orbital sander.

The standard orbital sander has a square or rectangular sanding pad that moves in a tight orbital motion, removing material quickly. This type of sander is usually classified by its size, which can range from a quarter sheet to a half sheet.

The quarter sheet orbital sander can hold a quarter sheet of nine by eleven standard size sandpaper, providing the user with four usable pieces out of one sheet. The half sheet orbital sander, on the other hand, holds a half sheet of sandpaper, providing two usable pieces out of one sheet. The sheets of sandpaper are attached to the sander with some sort of spring system or metal clamp that holds the paper to the sanding pad.

The random orbital sander, on the other hand, is characterized by a round sanding pad with round sanding discs that can be attached to the pad with either a pressure-sensitive adhesive or a hook and loop kind of like Velcro. the round sanding discs have factory holes that line up with the onboard dust collection to reduce dust while sanding. The random orbital sander not only moves in an orbital or ellipse motion but it spins as well, giving the sander the ability to remove a lot of material quickly.

While both sanders have their pros and cons, the random orbital sander is a great beginner tool. Regardless of what you buy, all new sanders come with some sort of dust collection bag. If you have to use sheets of standard sandpaper, be sure to punch holes in the paper so that the dust collection system can draw the sawdust up. It is always better to use a hose and a vac system than using the factory bag. These bags are great for small amounts of sanding but if you have to do a lot, consider using a vac.

Sanding Progression

The sandpaper grits are categorized based on their aggressiveness. The lower the number, the more aggressive the sandpaper removes the material, but the deeper the scratches. The higher the number, the less the sandpaper will remove, but the shallower the scratches. To achieve a smooth and even finish, it’s always best to progress through at least three to four sandpaper grits, starting lower and working your way up. Ultimately, through trial and error, you figure out your own progression for your specific tools and specific projects.

Basic Sanding Techniques

When sanding with a standard orbital sander, it’s important to remember that you always sand in the direction of the grain. If you’re not cautious, this sander will leave some really bad cross-grain scratches. On the other hand, the random orbital sander is much more forgiving and under normal operating conditions, it produces no cross-grain scratches.

It’s important to keep both sanders flat to the work. This is especially important with a random orbital sander because if you tip it in either direction for too long, it will create dips and valleys in your work. In addition, keeping the sander flat will also help reduce accidentally rounding over the edges if that’s something you’re not intending to do.

Lastly, it’s important to get a good uniform sanding over the entire workpiece. When using a standard orbital sander, you can start on the left and work your way to the right, always keeping the sanding motion with the grain and applying equal pressure. With the random orbital sander, the grain direction doesn’t really matter, so you can start and work in any direction you want. Just make sure you get uniform coverage.

To achieve a good uniform sanding over the entire workpiece, some people find it helpful to take a pencil and make light marks over the entire surface. What this does is allow them to gauge complete sanding coverage by visually giving them the ability to see if and when the pencil marks are gone.

Conclusion

Sanding wood is an art form that requires patience, diligence, and a willingness to learn from mistakes. Proper sanding techniques and using the right tool for the job can make all the difference in achieving a smooth and even finish on your woodworking projects. In this article, we covered basic sanding techniques, the different types of orbital sanders on the market, sanding progression, and dust collection.

Remember, when sanding with a standard orbital sander, sand with the grain, and keep the sander flat to the work. With the random orbital sander, the grain direction doesn’t matter, and it’s important to get a uniform sanding over the entire workpiece. Always progress through at least three to four sandpaper grits, starting lower and working your way up. Finally, for dust collection, it’s always better to use a hose and a vac system than using the factory bag.

This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.

[ad_2]

Source link